Home > Raw Material Partners > Oxidized Pan Fiber Home > Raw Material Partners > Oxidized Pan Fiber |

| |

What is Oxidized Pan Fiber?

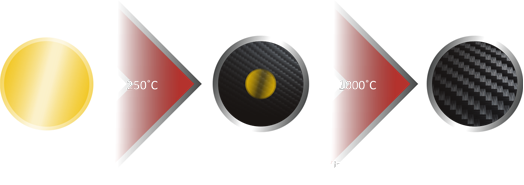

Oxidized Pan Fiberis also known as Preox, is the predecessor of carbon fiber. It is a special pan precursor oxidized in air oxidation furnace at a temperature between 200-300℃.When carbonized in inert atmosphere at 1000℃ and above, it then becomes carbon fiber. Carbon fiber is high in stretch resistance but extremely delicate which makes it unsuitable for applications in clothing. However OPF has been pre-burned, it is elastic and durable and very stable in heat. When exposed to direct flame, OPF will continue its carbonation without shrinking or burning, giving users extra time to extinguish the fire or escape.

|

|

| OPF is very unique among FR fibers, it is inherently non-flammable, it does not burn, melt, soften and possesses very high LOI (>50), flame-resistant up to 1000℃. It is also anti-bacterial, anti UV rays, resistant to electric and electric arc flash, molten metal splash and most of chemicals. It does not contain halogen,therefore it is safe both for the environment and human body. When exposed to flame and heat, OPF is able to maintain its size with limited contraction, this makes it the most suitable material for personal protection against splash and burn in high temperature working environments, as well as the best fire proof decorative material. OPF which has LOI higher than 50 can relatively increase the FR property of aramid fiber and extend skin protection time when exposed to flame and heat. |

| |

|